SMART FACTORY SOLUTIONS

Smart Factory Solutions empower industries to harness cutting-edge technologies like IoT, AI, and digital twins to optimize operations. By integrating advanced automation and predictive maintenance, manufacturers can achieve greater efficiency, reduce downtime, and enhance sustainability, aligning with the future of Industry 4.0. Explore how these innovative solutions can transform your manufacturing processes today.

Predictive Maintenance

Read More

Digital Twin

Read More

Visit our website for more information on projects.

Internet Of Things

Technologics is an innovative company specializing in IoT solutions tailored for smart factories. Our range of technologies and services is designed to revolutionize traditional factories into intelligent, interconnected, and data-driven environments. With an in-depth understanding of production processes and an unwavering commitment to innovation, our company consistently excels.

In an increasingly digitized manufacturing landscape, Technologics stands out as a premier supplier of smart Industrial Internet of Things solutions. We empower manufacturers to unlock unparalleled levels of efficiency, productivity, and competitiveness by leveraging cutting-edge technologies and a comprehensive grasp of production processes.

Fleet Management

Technologics’s Fleet Management Solution offers a comprehensive way to track your fleet’s time using Cloud-backed IoT networking. With real-time access to data captured from sensors installed in vehicles, you can ensure compliance with fleet security norms. This includes enhanced vehicle maintenance, fuel management solutions, prompt customer service, driver discipline, and location status.

Technologics offers a flexible, hardware-agnostic IoT architecture for connecting all possible assets—sensors, items, containers, equipment, vehicles, and employees.

Features of Our Fleet Management Solutions:

- Real-time fleet visibility

- Monitoring the entire fleet

- More accurate ETA predictions

- Driver activity monitoring

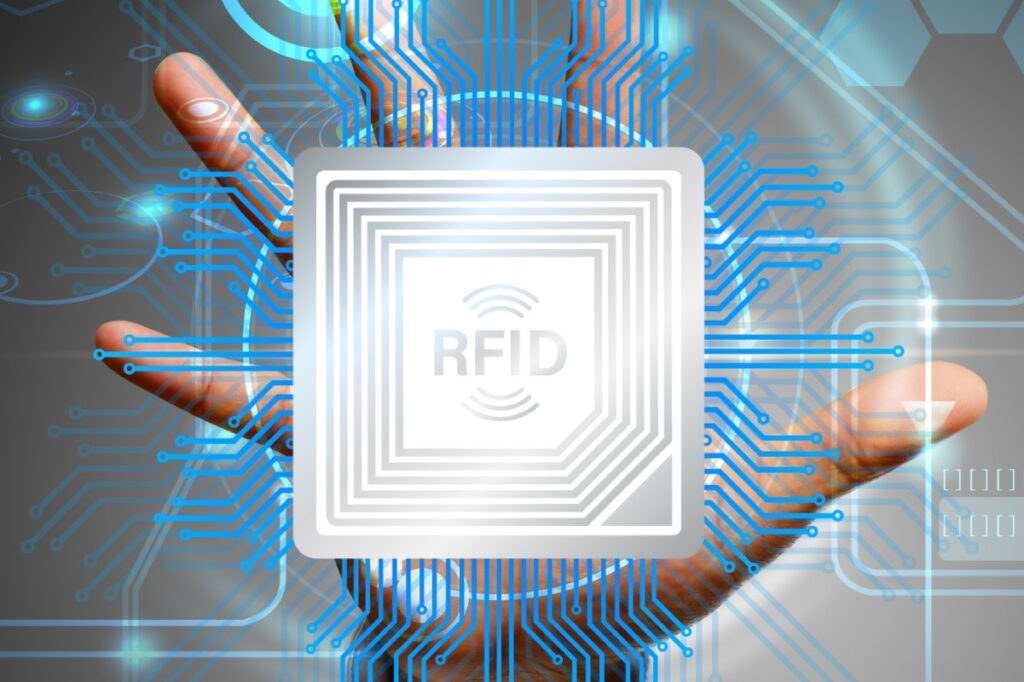

RFID Solution

From manufacturing to shipping, from the warehouse to the shop floor, encompassing promotions and loyalty cards, we provide an end-to-end Retail Inventory Management Solution. Our approach involves the integration of Radio Frequency Identification (RFID) technology with our software. This combination brings numerous benefits to the retail industry, fostering superior execution, enhanced operational efficiencies, and increased customer satisfaction through comprehensive analytics and inventory accuracy.

Employing high levels of encryption, RFID Tracking, and seamless integration into products, this solution serves effectively for authentication purposes.

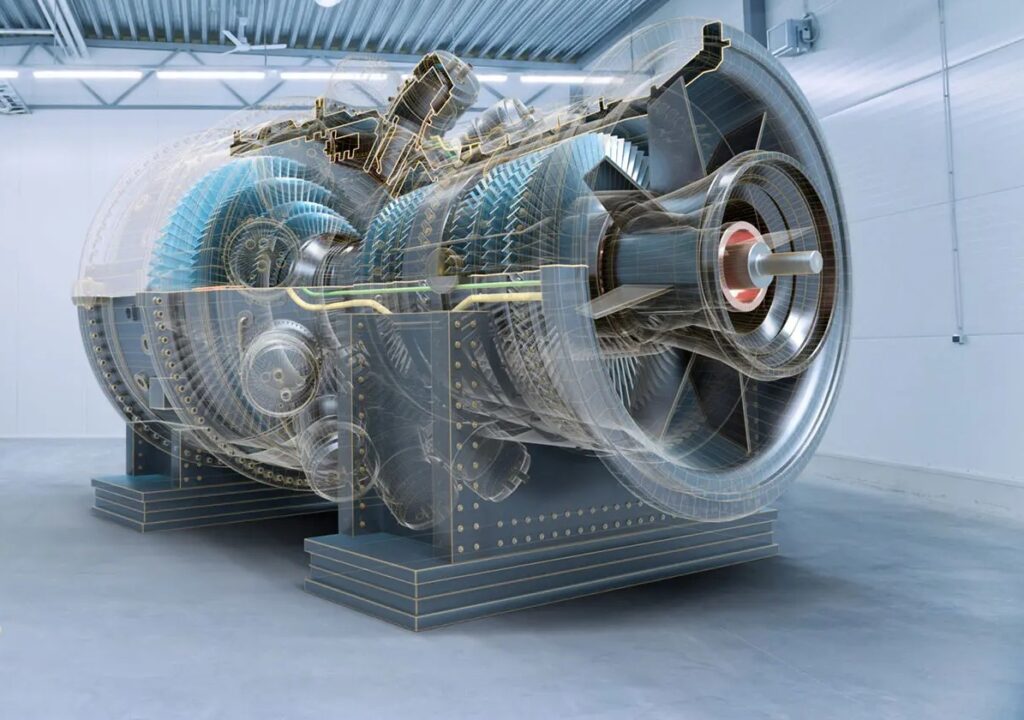

Predictive Maintenance

Predictive maintenance for industry 4.0 is a method of preventing asset failure by analyzing production data to identify patterns and predict issues before they happen.

How does Technologics IoT-based predictive maintenance work?

- Sensors

- Data communication

- Central data store

- Predictive analytics

- Root cause analysis

Digital Twin

Digital Twin offers a powerful way to monitor and control assets and processes.

Optimize business strategies and factory machine care with a Digital Twin Solutions & Technology, wherein a virtual copy of the entire value chain or a single machine is used to simulate, test, and optimize the processes and functionalities without loss to the business. Here’s What Technologics Offer

- Product/Process Virtualization & Control

- Production

- Customization

- AI-powered Recommendation

- Digital Twin in Healthcare

Smart Factory Solutions revolutionize traditional manufacturing by fostering seamless connectivity across the production ecosystem. IoT-enabled devices collect real-time data, offering valuable insights into machine performance and process optimization. Artificial intelligence enhances decision-making by identifying patterns, predicting potential failures, and recommending actionable solutions. Digital twins provide virtual replicas of physical systems, enabling manufacturers to simulate, analyze, and improve processes before implementing changes on the factory floor. These technologies collectively drive operational excellence by minimizing waste, conserving energy, and streamlining supply chains.

Moreover, Smart Factory Solutions empower businesses to adapt to market fluctuations with agility, ensuring consistent product quality and on-time delivery. By leveraging predictive maintenance, companies can preempt equipment breakdowns, reducing costly downtimes and maximizing productivity. This convergence of innovation not only boosts profitability but also aligns with global sustainability goals, paving the way for eco-friendly manufacturing. Embrace the transformative power of Industry 4.0 to stay ahead in today’s competitive landscape.